Your Cart is Empty

by Fiona McBryde May 18, 2021 3 min read

Good question. Getting someone else to make our soaps would be cheaper, quicker and easier. On the other hand, if we do the making, then we can choose our own suppliers, understand our ingredients, develop expertise and processes, keep our carbon footprint low. We get to check every single soap which gets sent out.

In short, we think by making by hand you get better soap and the planet gets a better deal too.

The definition of “handmade” is a bit wooly. The Handcrafted Soap & Cosmetic Guild allows for the use of ready made bases, so long as at least 50% of the process is handmade. Etsy, the online marketplace, includes in its definition, hand assembled, hand-altering, or even “bedazzling”.

We make all our soap in our workshop in Stroud. It’s made from scratch to the recipes we’ve developed and refined over several years using a traditional cold-process method. We use simple kitchen equipment - weighing scales, pans, bowls and spatulas.

Our recipe contains a high large of nourishing vegetable butters, which can be challenging to work with, as the different fats have different melting points and saponification rates (the amount of ingredient which can be converted into soap) It’s not as simple as putting everything in a bowl and giving it a good mix.

The soap is poured into moulds and depending on the outside temperature, and the particular soap we are making, covered with blankets, where it will sit for about 24 hours. The temperature will continue to rise as the soap completes the saponification process. When cool to touch, we take the soap out of the mould.

We cut the soap into bars and leave them to cure on the shelves. Offcuts or undersized bars are separated out and put into our All Kinds selection. Each soap is checked and given a quick trim and polish, before being wrapped. We oversee every step of the process to make sure we are happy with the quality of all the soaps.

Finally, the soaps are wrapped - we use paper packaging designed for us by Susie Hetherington, and printed for us locally. The wraps provide protection and help preserve the natural oils. And look lovely too!

The soaps are then shipped to our stockists across the UK, or sent directly to online customers, where they are used in a variety of handmade soap gift sets.

If you are a maker, whether you knit, bake or sew, you will know that there is something so satisfying about creating with your own hands. We feel greater connection to the final product because we make it. We do really value all your feedback, because ultimately we are making these soaps for you, so we want you to enjoy them.

We know the impact we are making on the planet too - that’s why it’s so important to us to make sure we source sustainable ingredients, keep our workshop as zero waste as possible and ensure the packaging we use is minimal and recyclable.

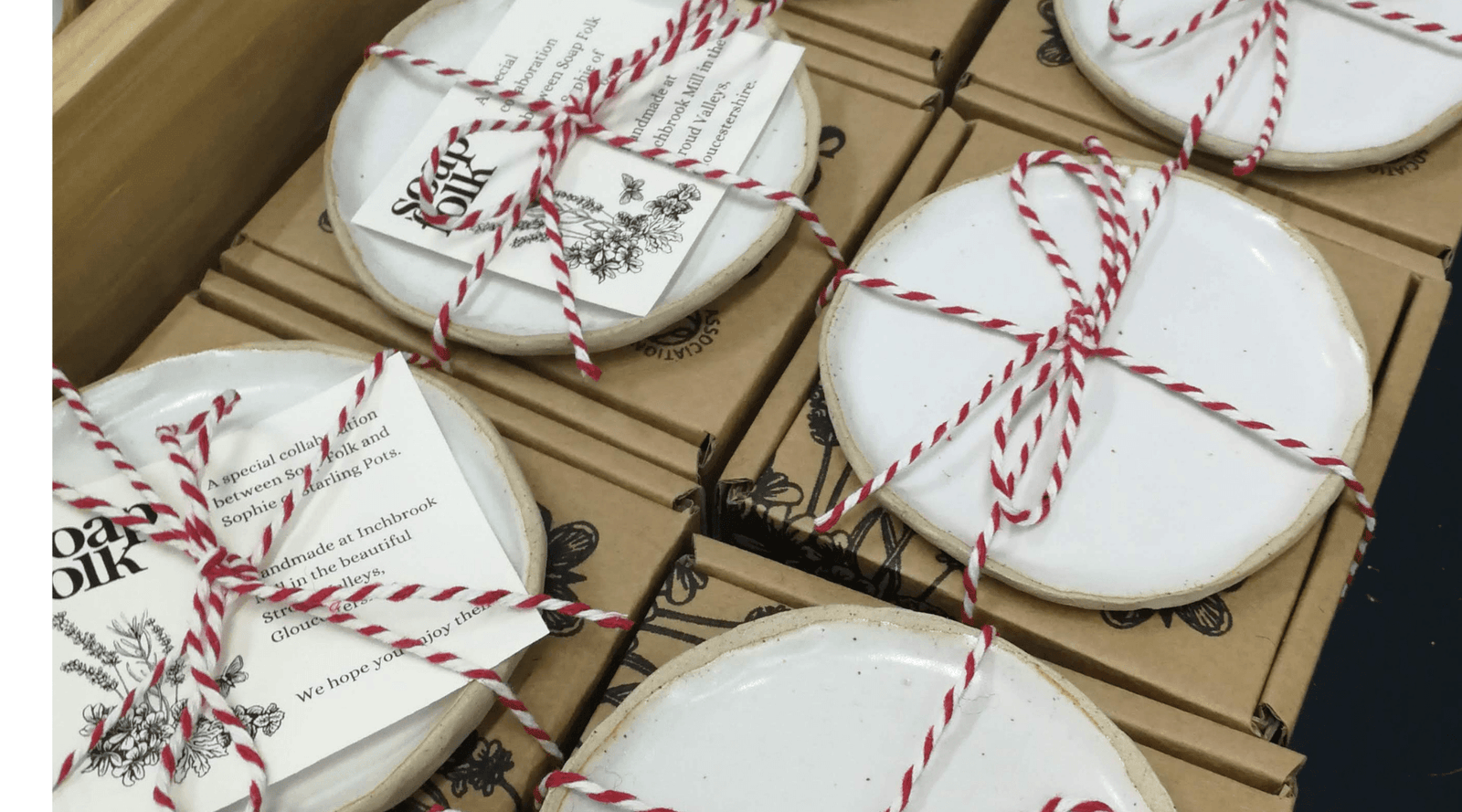

This level of detail makes us more creative - it’s hugely rewarding to collaborate with other makers who have the same high quality ethos, like Tom and Sophie who make our ceramic soap dishes.

It’s a cliche, but there really is a lot of love which goes into these soaps. Feeling passionate about what we make, we believe, shines through to the final bar. We love giving you the "Ooh factor". And for that reason, Soap Folk will always make soap by hand.

Comments will be approved before showing up.

by Fiona McBryde June 13, 2021 4 min read

by Fiona McBryde May 29, 2021 3 min read

by Fiona McBryde May 23, 2021 2 min read

Sign up to get the latest blogs, exclusive offers and giveaways